Gentle processing for optimum texture and taste

-

LET’S TALK

Mayonnaise

& more

Customized Solutions for Your Mayonnaise Production

ProXES offers customized and highly efficient technologies for every step of mayonnaise production. From ingredient processing to the final product, our integrated systems ensure the highest quality and maximum efficiency. Whether you’re producing traditional mayonnaise, vegan alternatives, or unique recipes, we provide advanced machinery, expert support, and innovative solutions. These help you streamline production, achieve your goals efficiently, and ensure consistent, sustainable results.

Did You Know?

The classic mayonnaise recipe is believed to have been invented in 1756 during a siege on the French island of Menorca. French chefs improvised with oil, egg yolk, and vinegar when cream was unavailable.

Today, modern machines can produce up to 10,000 liters of mayonnaise per hour—efficient, precise, and delicious!

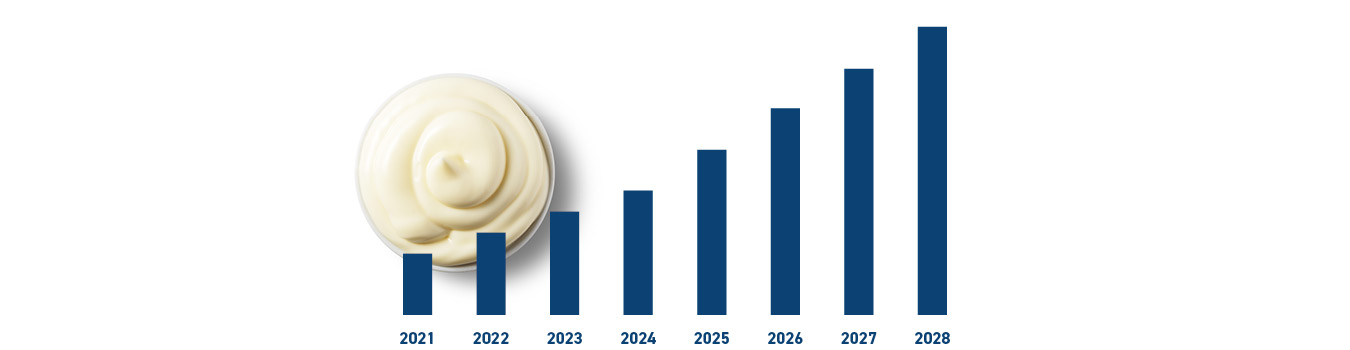

Why Investing in Mayonnaise is Worthwhile

Mayonnaise is a staple in households and foodservice globally, and its market continues to grow steadily. With increasing demand for plant-based options, low-fat alternatives, and convenience foods, the mayonnaise market is projected to reach USD 10 billion by 2028, with an average annual growth rate of 4.1%. With ProXES processing systems, you can seize this growth opportunity and efficiently expand your production capacity— whether you're producing small batches or large volumes. (Data Bridge Market Research Analysis Study 2023)

Regional Insights

North America: This region is expected to hold a dominant share of the market, driven by increasing interest in premium and vegan mayonnaise products

Europe: Countries like Germany, France, and the UK are key players, with rising demand for both traditional and low-calorie mayonnaise

Asia-Pacific: Rapid growth in countries like China, India, and Japan is fueled by expanding fast food culture and increasing disposable income

Latin America and Middle East/Africa: These regions are also seeing steady growth, particularly driven by new product innovations and expanding urbanization

How to produce mayonnaise

Mayonnaise Production Lines: Hot vs. Cold

With ProXES, you have full flexibility to adapt your mayonnaise production to your exact requirements—whether through hot or cold production methods. Our state-of-the-art machines, including our ProxxD and Combitherm, ensure optimal results regardless of the chosen method. Together, we’ll optimize your processes to meet your specific needs, whether for regulatory compliance or market preferences.

Benefits of Cold Processing

- Simple manufacturing process with raw ingredients

- Energy efficient (no heating, coolingor steam)

- Low initial investment

- Low maintenance, low cost of ownership

Different Mayonnaise Variations? No Problem!

Mayonnaise is a staple in households and foodservice globally, with increasing demand for plant-based options, low-fat alternatives, and convenience foods. With ProXES processing systems, you can efficiently expand your production capacity, whether you're producing small batches or large volumes.

Flexibility and Adaptability

With modular extensions like the CuliFlex technology, you can significantly expand your product range. Our systems are designed for traditional mayonnaise as well as modern alternatives like vegan or low-fat varieties, along with dressings and sauces. This flexibility allows you to quickly adapt to market changes without the need for additional investment.

Optimal Mayonnaise Production Systems for Every Requirement

Our state-of-the-art ProXES processing systems, such as ProxxD and CuliFlex, set new standards in producing high-quality emulsions. The ProxxD enables a significant increase in production capacity while reducing energy consumption per kilogram of product. The combination of ProxxD and CuliFlex creates a highly efficient continuous processing line capable of producing both full-fat and low-fat mayonnaise.

-

Proxx DHigh-Efficiency Emulsification

The ProxxD is a multifunctional processing unit designed for high-quality emulsions and suspensions. It increases production capacity significantly while reducing energy consumption per kilogram of product. Its intuitive operation and programmable process parameters ensure consistent, reproducible results.

- CuliFlexVersatile Continuous Processing

-

MicroCutPrecision Cutting and Homogenization

MicroCut ensures ultra-fine cutting and precise homogenization, which is crucial for achieving a stable and smooth mayonnaise texture. Its high shear technology guarantees uniform particle size and consistent product quality.

-

VacuthermVacuum Processing for Maximum Quality

The Vacutherm system provides vacuum processing to prevent air incorporation, ensuring a homogenous emulsion and extended product shelf life. This system is ideal for both mayonnaise and emulsified sauces, maintaining consistent product density.

-

CombithermLarge Batch Processing with Direct Heating

Combitherm units are designed for large-scale production, offering a usable volume of up to 1,200 liters and hourly outputs of up to 3,600 kg/h. They support both direct steam injection and indirect heating, ensuring fast and gentle processing with minimal energy loss.

-

Stephan Universal MachineCompact and Flexible

Stephan Universal Machines are perfect for small to medium batch production, with capacities of up to 1,000 kg/h. They excel in both hot and cold processing and offer a high level of flexibility for various product types.

New Ideas for Mayonnaise?

Co-Creation Solutions for Customized Production

At ProXES, we believe that innovation is key to staying competitive in the evolving mayonnaise market. Our co-creation approach is to support you through every stage of product and process development. Whether you're formulating a new recipe, refining an existing one, or expanding production to meet growing demand, our team of experts is here to collaborate with you.

We provide a comprehensive range of services in our state-of-theart Technology Centers, where you can trial new ingredients, test different formulations, and simulate production conditions. By working closely with our technical and technological specialists, you’ll have the opportunity to refine and optimize your mayonnaise products for both quality and scalability.

From small-scale test runs to full-scale production, ProXES offers flexible solutions that ensure smooth transitions between product development and market readiness. Our co-creation process empowers you to innovate confidently, whether you're exploring new categories such as vegan, low-fat, or organic mayonnaise, or improving the consistency, texture, and shelf life of traditional recipes.

With our deep industry expertise and cutting-edge technology, you can turn your innovative ideas into commercially successful products, while responding rapidly to consumer trends and market demands.

Think Mayonnaise – And So Much More

Why limit yourself to mayonnaise when ProXES can help you create much more? Our advanced processing technologies support the production of sauces, soups, and sauces with the highest precision and quality.

Whether it’s small-batch production or high-volume output, ProXES systems are tailored to meet your exact requirements – ensuring flexibility and reliable performance across a wide range of applications.

High-Performance Mayonnaise Lines for Large Production Volumes

For large-scale industrial mayonnaise production, ProXES offers complete, customized solutions tailored to the unique demands of highvolume manufacturers. Our systems combine high efficiency with superior product quality, ensuring that you can consistently meet production targets without compromising on standards. By integrating advanced technologies like ProxxD, we provide seamless, energy-efficient operations designed to boost productivity while reducing costs. Whether you're expanding your product range or scaling up existing operations, ProXES sets new standards in industrial food production, helping you stay competitive in an evolving market.

Results that convince

ProXES embodies innovation through strong partnerships and groundbreaking solutions. In collaboration with leading food manufacturers, we’ve redefined standards in mayonnaise production. One of our trusted long-term partners, renowned for their expertise in sauces and spreads, seamlessly integrated our systems into their operations. The outcome? Enhanced production efficiency, faster development cycles, and the launch of exciting new mayonnaise varieties—all achieved in just a few months.

Download our latest brochure to learn more.

AND WHAT ABOUT KETCHUP?

Mayonnaise, salad dressings, tartar sauce or ketchup – if you want to produce it, ProXES can deliver. Our versatile processing systems are designed to prepare a wide range of sauces. Ask our experts about modular extensions customized to your requirements!