On-the-go cheese products are growing. Consumers want high protein, low carb snacks with simple ingredients.

-

THINK

Processed &

cream cheese

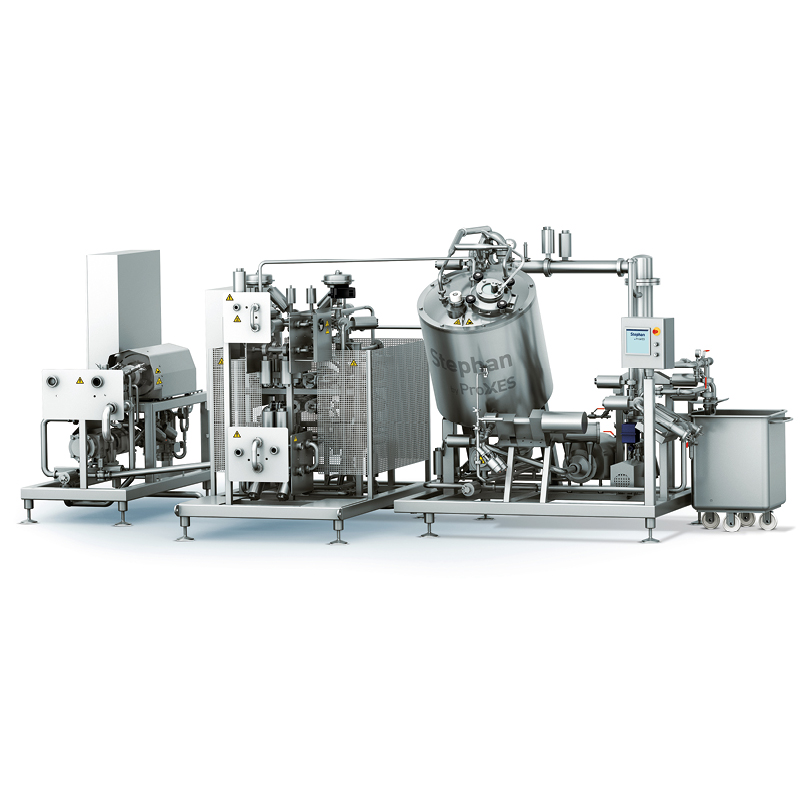

Processing Solutions for Cream Cheese & Processed Cheese

ProXES delivers machines and process solutions for the industrial production of cream cheese and processed cheese. Our technologies enable efficient manufacturing, consistent product quality, and the flexibility to respond to today’s food trends such as clean label, plant-based alternatives and functional cheese products.

Global Market Insights: Cream and Processed Cheese

The global market for cream and processed cheese continues to grow steadily, driven by consumer demand for convenience, snacking options, and plant-based alternatives.

Key market insights:

- Cream cheese market: Valued at USD 9.1 billion in 2025, projected to reach USD 11.3 billion by 2035 (CAGR 5.9%) – Future Market Insights, 2025

- Processed cheese market: Estimated at USD 17.7 billion in 2025, expected to grow to USD 24.4 billion by 2035 (CAGR 3.3%) – Future Market Insights, 2025

- Combined market: Worth USD 20.3 billion in 2023, forecast to reach USD 27.5 billion by 2032 (CAGR ~3.45%) – WiseGuy Reports, 2023

Turning Market Trends into Business Success

The global cream cheese and processed cheese markets are expanding. But numbers alone are not enough.

Growth is fueled by strong consumer shifts: demand for convenient on-the-go products, the rise of flexitarian and vegan lifestyles, and clean label regulations.

For manufacturers this means both opportunity and pressure. Those who adapt quickly can secure shelf space, win new contracts and expand market share. Delaying investments risks falling behind competitors who are already scaling their capacities and launching innovative products.

With ProXES you can react faster. Our technology and co-creation centers shorten development cycles, support recipe adjustments and deliver the flexibility needed for future growth.

Global Consumer Trends

Your Challenges and Our Solutions

Manufacturers face increasing complexity. ProXES provides support in key areas:

- Flexibility for international markets such as UHT sterilized products, plant-based variants and regional flavor profiles.

- Efficiency gains through reduced batch times, fast CIP cleaning and consistent quality.

- Packaging versatility with cups, blocks, tubs, tubes and portion packs

Batch or Continuous Production – Which Fits Your Business?

-

UHT (production line)For extended shelf life of your processed cheese

- Continuous UHT sterilisation ensures extended shelf life for all processed cheese types

- High throughput with consistent product quality

- Fast and efficient mixing for optimal texture and taste

- Lower production costs through continuous operation

- Flexible processing for spreads, blocks, and slices

- High capacity: over 2,000 kg/h for spreads and 1,000 kg/h for block and slice cheese

- Compact, hygienic design with easy cleaning and maintenance

-

CombithermDeveloped for large-scale production

- Versatile system that can handle various processing steps

- High capacity, suitable for large production quantities

- Ensures optimum product quality through precise temperature contro

-

VacuthermDeveloped for large-scale production with the finest homogenization

- Combines efficient cooking and cooling processes

- With direct steam injection for fast and gentle heating

- Provides consistent product quality and extended shelf life.

-

Universal machinesIdeal for the production of small to medium batches

- Versatile and adaptable to different recipes and production volumes

- Efficient manufacturing with options for direct or indirect heating and cooling

- Ensures high quality and consistent results with minimal waste.

-

Cook-ItCompact batch cooking solution

- Ideal for small and medium production volumes

- Flexible processing for spreads, sauces, processed cheese and more

- Efficient heating and mixing for consistent product quality

- Compact footprint — easy integration into existing lines

- Fast cleaning and changeover for high production uptime

- Designed for reproducible results and energy efficiency

how to produce block cheese

Co-Creation for Cheese Excellence

Our five global ProXES Technology Centers offer real-life testing, process development, and scaling support. Collaborate with our experts to refine your recipe, test new ingredients, or optimize your production –

in a space made for innovation.

SPREADS: SAVORY, SWEET OR NUTTY?

Chocolate spreads, veggie dips, peanut butter or hummus – if you want to produce it, ProXES can deliver! Our versatile processing systems are designed to prepare a wide range of spreads. Ask our experts about modular extensions customized to your requirements!

Download our latest brochure to learn more.

INTERVIEW: GLOBAL TRENDS ON PROCESSED CHEESE