-

Deaerators

Efficient vacuum process systems for deaeration and degassing in the batch area

De-aeration – or more generally: degassing – is an essential process step to ensure or increase the quality of emulsions and suspensions. ProXES relies on the mechanical process using vacuum for the deaeration/degassing of flowable products. Depending on the application, manufacturing process and product, you can choose between vacuum process systems in batch operation or in-line vacuum deaerators in continuous operation. Our ProXES specialists will be happy to advise you on this. Together, we can also determine whether a dynamic or static venting process is most appropriate for your products.

Our vacuum process systems for deaeration and degassing:

-

Vacuum Deaerator Continuous automatic removal of air

- Capacities up to 30.000 kg/hour*

- From lab to industrial scale

- Functions:

- vacuum deaeration

- Main applications:

- mustard

- paper coatings

- honey

- liquid detergents

- carbomer suspensions

- lubrication grease

*Application: low viscous products

-

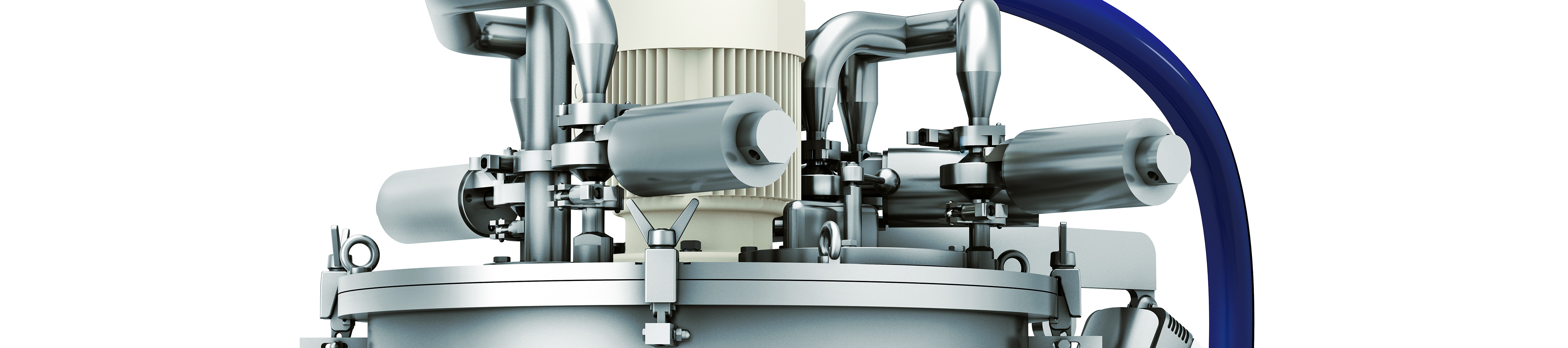

DinexPersonal Care & Pharma high shear emulsifier

Capacities up to 3,000 kg/hour*

- Functions:

- homogenizing

- mixing

- dispersing

- deaeration

- cooling

- heating

- cleaning

- sterilization

- Main applications:

- cosmetics

- sterile pharmaceuticals

- cream

- ointment

- gels

- toothpaste

*Application cold processed emulsion standard FrymaKoruma formulation

- Functions:

-

VMEUniversal mixing and dispersing

- Capacities up to 1,700 kg/hour*

- From lab to industrial scale

- Functions:

- homogenizing

- mixing

- dispersing

- heating

- cooling

- deaeration

- deagglomeration

- Main applications:

- toothpaste

- creams

- sealants

- lotions and pastes

*Application toothpaste standard FrymaKoruma formulation

-

ProxxDHigh-class emulsifier

- Production capacity for

full fat mayonnaise: up to 6,000 kg/h*

- Production capacity for

low fat mayonnaise (30% oil): up to 4,000 kg/h*

- Oil dosing: up to 3.0 kg/s

- Specific energy input: on average 5 kWh/ton

- Batch volume: 500 l

- Dimensions – basic concept: L 230 x H 280 x W 210 cm

- Weight: approx. 2,000 kg

*Based on FrymaKoruma standard recipies and dependent on system configuration.

Download our latest brochure to find out more about our products.

- Production capacity for