-

Stephan.

WE ARE PROXES.

High-performance universal machines for the food industry

For over 60 years, Stephan has stood for customized machinery and equipment in the food processing industry – with a strong focus on convenience products, dairy, and confectionery. As part of the ProXES Group, Stephan supplies leading food brands worldwide with tailor-made solutions that enhance efficiency and support production processes – from initial idea to final application.

Customized process technology for the food industry

-

Combitherm Flexible and multifunctional batch processing

- Capacities up to 4,800 l/hour*

- Functions:

- mixing

- emulsifying

- dispersing

- direct/indirect heating

- frequency controlled knifes

- vacuum processing

- Main applications:

- mayonnaise

- ketchup

- dressings

- dips

- baby food

- sauces

*Application: low viscous products

Download our latest brochure to find out more about our products.

-

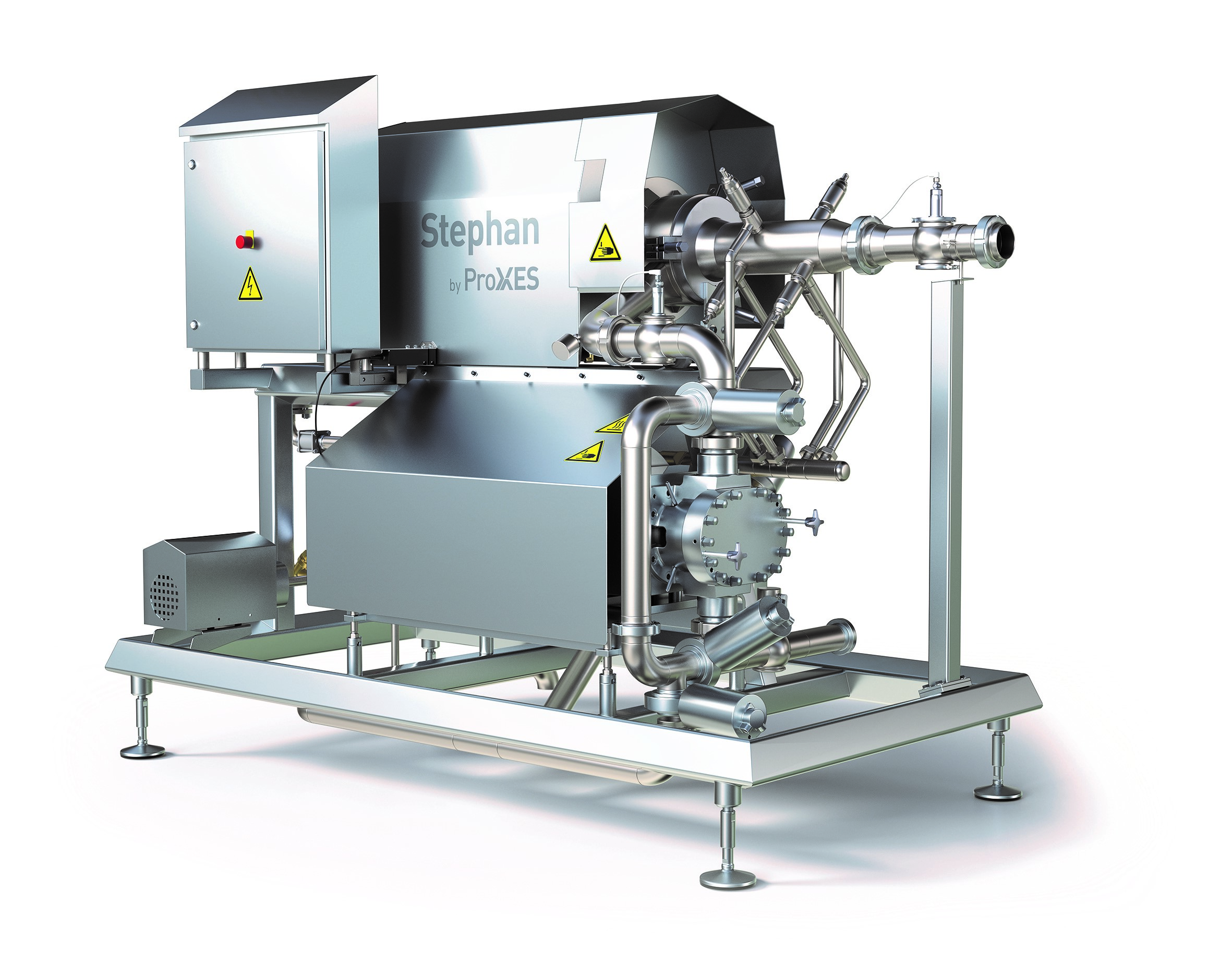

Continuous CookerInline high-shear unit

- Capacities up to 6.000 l/hour*

- Functions:

- cutting

- dispersing

- emulsifying

- homogenizing

- Main applications:

- processed cheese

- vegetable purees

- ketchup and other sauces

*Application: spreadable processed cheese for jars or triangle portions

Download our latest brochure to find out more about our products.

-

Cook-ItCompact batch cooking solution

- Capacities up to to 3,600 l/hour*

- Functions:

- heating up to 95 °C

- tiltable vessel

- direct steam injection

- double jacket heating and cooling

- Main applications:

- Stew, soups and sauces

- Side dishes

- Processed cheese

*Application: low viscous products

Download our latest brochure to find out more about our products.

-

Microcutperfect for fine cutting and emulsifying

- Capacities up to 4,500 l/hours (stand alone setup)*

- Capacities up to 15,000 l/hours (inline setup)*

- Functions:

- cutting

- dispersing

- emulsifying

- homogenizing

- Main applications:

- rework

- meat emulsions

- vegetable grinding

*Application: low viscous products

** Exemplary illustration

Download our latest brochure to find out more about our products.

-

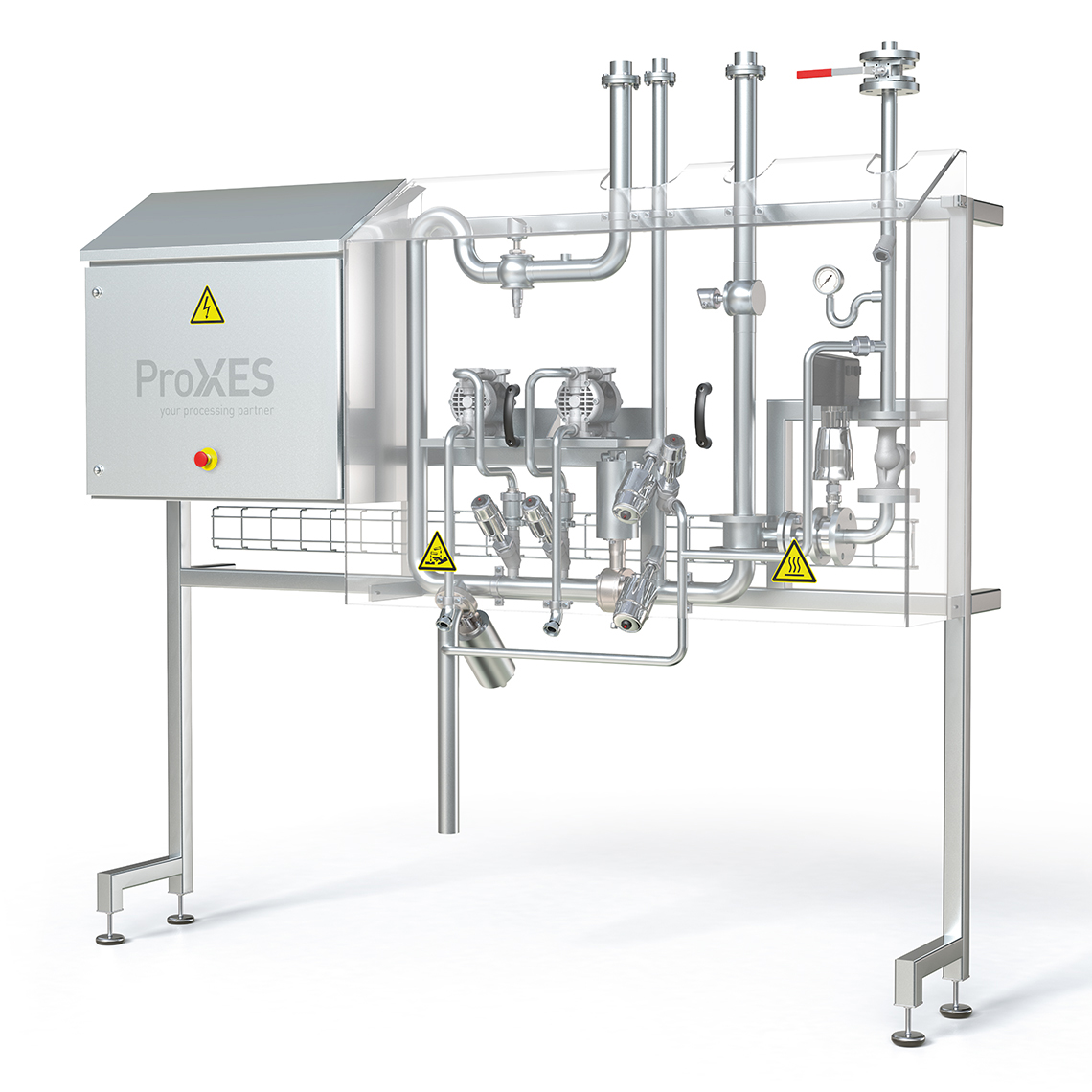

ProCIP CompactInternal single-use cleaning

- Single- use and recovery systems

- Tank capacities up to 20.000 l

- Throughput up to 50m³/h

- Functions:

- Preparation of cleaning solutions

- Storage of cleaning solutions (Recovery)

- Distribution of cleaning solutions

- Monitoring

- Reporting

- Main applications:

- Tank cleaning

- Pipe cleaning

- Combined cleaning objects

-

ProCIP RecoveryExternal recovery re-use cleaning

- Single- use and recovery systems

- Tank capacities up to 20.000 l

- Throughput up to 50m³/h

- Functions:

- Preparation of cleaning solutions

- Storage of cleaning solutions (Recovery)

- Distribution of cleaning solutions

- Monitoring

- Reporting

- Main applications:

- Tank cleaning

- Pipe cleaning

- Combined cleaning objects

-

ProCIP SExternal batch single- cleaning

- Single- use and recovery systems

- Tank capacities up to 20.000 l

- Throughput up to 50m³/h

- Functions:

- Preparation of cleaning solutions

- Storage of cleaning solutions (Recovery)

- Distribution of cleaning solutions

- Monitoring

- Reporting

- Main applications:

- Tank cleaning

- Pipe cleaning

- Combined cleaning objects

**illustrative example

-

SAMAseptic multifunctional processing unit

- Capacities up to 1,600 l/hour*

- Functions:

- heat- processing (direct)

- cooling (indirect / condensing)

- CIP

- SIP

- Main applications:

- baby / senior food

- pureed food / fruit puree

- classical sauces

- sauces & soups with particles

- fruit preparations

- desserts/ milk desserts

*Application: low viscous products

-

UHT SystemContinuous ultra-high temperature processor

- Capacities up to 6,000 kg/hour

- Functions:

- pre- heating if required

- heating up to 145 °C

- vacuum deaeration

- Flash- cooling down to 80…85°C

- Creaming

- Homogenizing if required

- Main applications:

- Heat treatment of processed cheese from low to high viscosity

Download our latest brochure to find out more about our products.

-

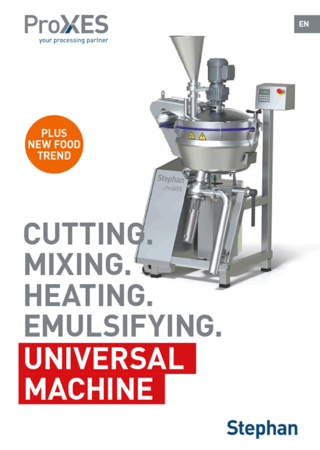

Universal Machine Perfect for small & medium batches

- Capacities up to 1000 l/hour*

- From lab to industrial scale

- Functions:

- direct/indirect heating up to 125 °C

- Vacuum processing

- Mixing, cutting and emulsifying

- indirect cooling via double jacket

- Main applications:

- dairy (processed cheese)

- convenience food (purées, saucen)

- confectionary (ganache)

*Application: low viscous products

**Exemplary illustration

Download our latest brochure to find out more about our products.

-

Universal Machine 12Compact universal mixer designed for efficient mixing, emulsifying, and pureeing

Typical Applications:

- Pastries & Dough

- Dressings, sauces

- Mayonnaise, ketchup

- Shredded Cheese

- Pureed food

Advantages:

- Efficient mixing

- Perfect cut

- Pureeing

- Emmulsifying

- Constant product quality

- Easy to operate & clean

- No-contact cutting system

- Versatile dough kneader & blade attachments

Download our latest brochure to find out more about our products.

-

Universal Machine 74Efficient mixing, emulsifying, and pureeing

Typical Applications:

- Pastries & Dough

- Dressings, sauces

- Mayonnaise, ketchup

- Shredded Cheese

- Pureed food

Advantages:

- Efficient mixing

- Perfect cut

- Pureeing

- Emmulsifying

- Constant product quality

- Easy to operate & clean

- No-contact cutting system

- Versatile dough kneader & blade attachments

Download our latest brochure to find out more about our products.

-

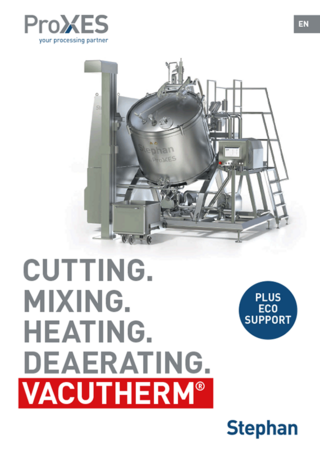

Vacutherm Efficient hot & cold processing

- Capacities up to 4,800 l/hour*

- Functions:

- mixing

- emulsifying

- dispersing

- direct/indirect heating

- indirect cooling

- Vacuum processing

- Main applications:

- mayonnaise

- ketchup

- dressings

- dips

- baby food

- sauces

*Application: low viscous products

Download our latest brochure to find out more about our products.