-

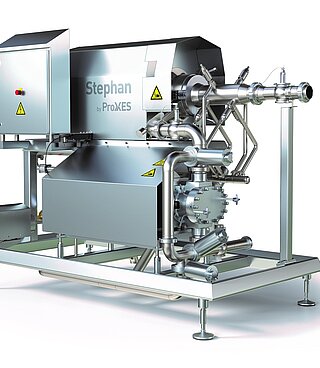

Stephan.

WE ARE PROXES.

High-performance universal machines for the food industry

Stephan stands for the design and manufacture of machines and plants for the food processing industry. With more than 60 years of experience in the food industry, especially in the field of convenience products, dairy and confectionery, Stephan supplies the leading food brands with customer-optimised machines and systems to support production processes and increase efficiency.

Customized process technology for the food industry

-

Universal Machine perfect for small & medium batches

- Capacities up to 1000 l/hour*

- From lab to industrial scale

- Functions:

- direct/indirect heating up to 125 °C

- Vacuum processing

- Mixing, cutting and emulsifying

- indirect cooling via double jacket

- Main applications:

- dairy (processed cheese)

- convenience food (purées, saucen)

- confectionary (ganache)

*Application: low viscous products

**Exemplary illustration

-

COOK-IT® compact batch cooking solution

- Capacities up to to 3,600 l/hour*

- Functions:

- heating up to 95 °C

- tiltable vessel

- direct steam injection

- double jacket heating and cooling

- Main applications:

- Stew, soups and sauces

- Side dishes

- Processed cheese

*Application: low viscous products

-

Combitherm flexible and multifunctional batch processing

- Capacities up to 4,800 l/hour*

- Functions:

- mixing

- emulsifying

- dispersing

- direct/indirect heating

- frequency controlled knifes

- vacuum processing

- Main applications:

- mayonnaise

- ketchup

- dressings

- dips

- baby food

- sauces

*Application: low viscous products

-

Vacutherm efficient hot & cold processing

- Capacities up to 4,800 l/hour*

- Functions:

- mixing

- emulsifying

- dispersing

- direct/indirect heating

- indirect cooling

- Vacuum processing

- Main applications:

- mayonnaise

- ketchup

- dressings

- dips

- baby food

- sauces

*Application: low viscous products

-

SAM®aseptic multifunctional processing unit

- Capacities up to 1,600 l/hour*

- Functions:

- heat- processing (direct)

- cooling (indirect / condensing)

- CIP

- SIP

- Main applications:

- baby / senior food

- pureed food / fruit puree

- classical sauces

- sauces & soups with particles

- fruit preparations

- desserts/ milk desserts

*Application: low viscous products

-

Microcut perfect for fine cutting and emulsifying

- Capacities up to 4,500 l/hours (stand alone setup)*

- Capacities up to 15,000 l/hours (inline setup)*

- Functions:

- cutting

- dispersing

- emulsifying

- homogenizing

- Main applications:

- rework

- meat emulsions

- vegetable grinding

*Application: low viscous products

** Exemplary illustration -

CombicutMultifunctional and Efficient

Capacities up to 3,480 l/hour*

- Functions:

- cutting

- mixing

- emulsifying

- powder dispersion

- direct steam injection (DSI)

- vacuum processing

- Main applications:

- processed cheese

- vegan cheese alternatives

- marzipan

- surimi

- horseradish

- liver paté

*Application: Processed cheese, spreadable

- Functions:

-

Continuous CookerInline high-shear unit

- Capacities up to 6.000 l/hour*

- Functions:

- cutting

- dispersing

- emulsifying

- homogenizing

- Main applications:

- processed cheese

- vegetable purees

- ketchup and other sauces

*Application: spreadable processed cheese for jars or triangle portions

-

UHT Systemcontinuous ultra-high temperature processor

- Capacities up to 6,000 kg/hour

- Functions:

- pre- heating if required

- heating up to 145 °C

- vacuum deaeration

- Flash- cooling down to 80…85°C

- Creaming

- Homogenizing if required

- Main applications:

- Heat treatment of processed cheese from low to high viscosity

Your contact person for Food-Applications:

Stephan Lyke

+49 173 744 30 89

Your contact person for HPC, Pharma and Chemical applications:

Thomas Schöck

+49 1607 2743 50