-

Wet Grinders /

Mills

Precision and variety in wet milling

ProXES has specialized in wet milling. This means that the products to be shredded must be flowable, pumpable or have a certain residual moisture. Our portfolio offers different technologies for cutting, which individually or in combination cover a wide range of particle sizes - from several centimeters of initial size to target sizes of a few micrometers, in special cases even nanometers. These technologies can also be used to cut and disperse fibrous starting materials, keyword: milk derivatives.

Discover our advanded processing plants for wet milling and dispersion

-

Perforated Disc Mill powerful grinding and pre-grinding

- Capacities up to 40,000 kg/h* (Inline)

- Capacities up to 10,000 kg/h** (Stand- alone)

- From lab to industrial scale

- Functions:

- pre-grinding

- pulping

- mashing

- Main applications:

- fruit and vegetable

- soya beans slurry

- meat and fish pastes

- pet food

- chemical suspensions

- paper coatings

- polymers

*Application: low viscous products / **Application: whole vegetables; coarse paste

-

Toothed Colloid Mill variable wet milling

- Capacities up to 40,000 kg/h* (Inline)

- Capacities up to 5,000 kg/h** (Stand- alone)

- From lab to industrial scale

- Functions:

- wet fine grinding

- dispersing

- emulsifying

- Main applications:

- soy, rice, oat slurry

- nuts & seeds pastes

- tablet coatings

- decorative cosmetics

- creams & ointments

- chemical suspensions

- lubrication grease

*Application: low viscous products / **Application: Nuts & Seeds; coarse paste

-

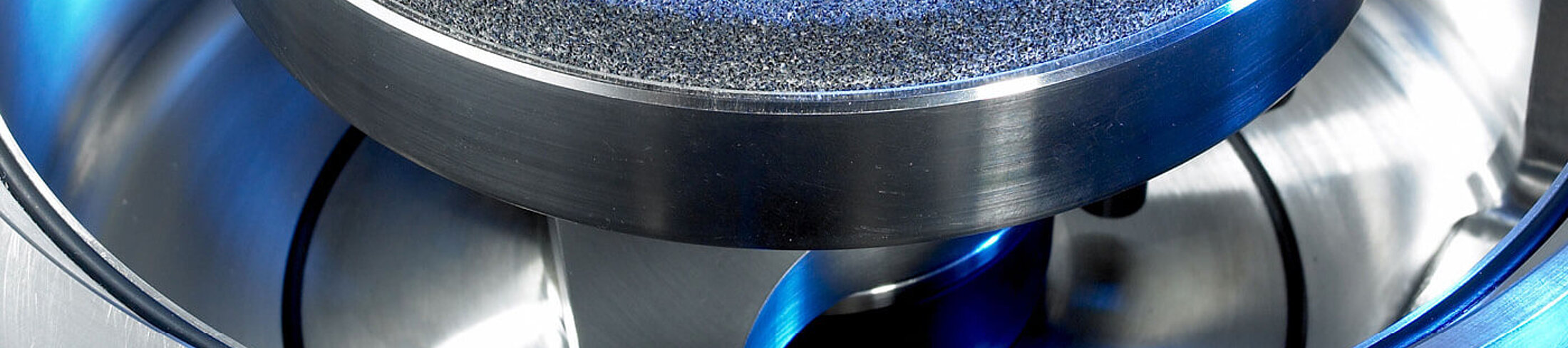

Corundum Stone Millversatile wet milling and dispersing

- Capacities up to 5,000 kg/h* (Inline)

- Capacities up to 3,000 kg/h (Stand- alone)

- From lab to industrial scale

- Functions:

- wet fine grinding

- dispersing

- Main applications:

- mustard

- tahina

- nut & seed pastes

- cocoa nibs

- softgel fillings

- Pigments slurries

- agro chemicals

*Application: low viscous products / **Application: Nuts & Seeds; coarse paste

-

Co-Ball Millhigh-performance very fine grinding

- Capacities up to 1.000 kg/hour* (Inline setup)

- From lab to industrial scale

- Functions:

- ultra fine grinding

- Main applications:

- paints and varnishes

- softgel fillings

- lipstick masses

- chocolate fillings and creams

- API suspension

*Application cocoa liquer

Download our latest brochure to learn more.

PLANT-BASED DRINKS WEBINAR

March 27, 2024 – 9 am and 4 pm

Immerse yourself with us in the world of vegan beverage processing and learn more about the key technology of wet milling.

Your contact person for Food-Applications:

Stephan Lyke

+49 173 744 30 89

Your contact person for HPC, Pharma and Chemical applications:

Thomas Schöck

+49 1607 2743 50